How Generative AI Is Transforming Manufacturing SOPs, Work Instructions, and QC Reports

- Mark Chomiczewski

- 23 January 2026

- 4 Comments

For decades, manufacturing teams have struggled with outdated, static documents. Paper manuals gather dust. PDFs on shared drives are impossible to search. Work instructions written in 2012 don’t reflect the new torque settings installed last month. Quality control reports are filled out by hand, then lost in binders. It’s slow. It’s error-prone. And it’s costing factories time, money, and safety.

Now, generative AI is changing all of that-not by replacing people, but by giving them the right information, at the right time, in the right way. Factories in Georgia, Michigan, and Bavaria are already using AI to generate Standard Operating Procedures (SOPs), dynamic work instructions, and real-time QC reports. The results? New hires are productive in days, not weeks. Downtime is dropping. Mistakes are falling by nearly half.

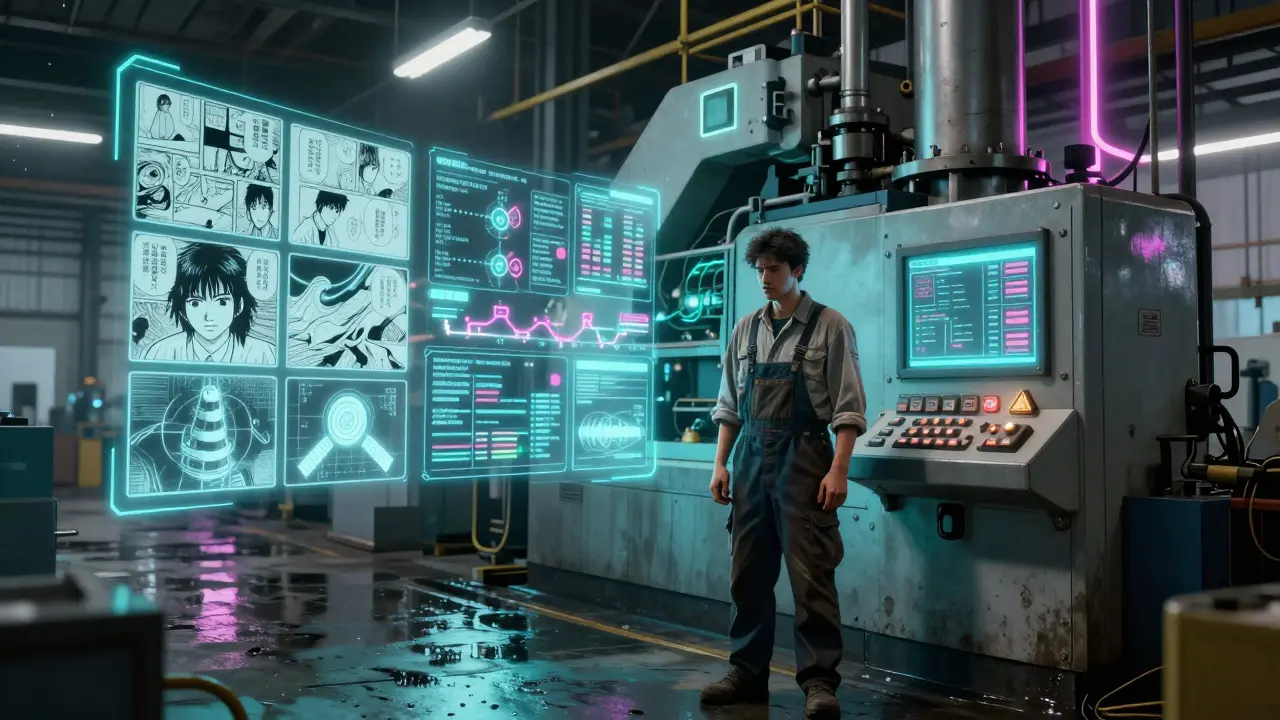

What Generative AI Actually Does on the Shop Floor

Generative AI in manufacturing doesn’t just rewrite old documents. It builds them from scratch-using live data. Think of it as a smart assistant that knows every machine, every error code, every past repair, and every operator’s question from the last 18 months.

When an operator pulls up a work instruction for assembling a brake caliper, the AI doesn’t show a fixed PDF. It pulls data from the machine’s sensor logs, checks the last 50 similar jobs, sees that torque specification changed last Tuesday, and generates a custom step-by-step guide-complete with images, warnings, and even a video clip of the correct technique. All in under 3 seconds.

At Georgia-Pacific’s paper mill, operators ask questions like, “Why is the dryer belt slipping again?” The AI doesn’t point to a 40-page manual. It analyzes temperature trends, belt wear history, and recent maintenance logs, then delivers a 200-word fix with steps tailored to that exact machine. They now handle over 12,000 queries a day-with 92% accuracy.

How SOPs Are No Longer Static Documents

Traditional SOPs are like roadmaps printed in 1995. They don’t adapt when the road changes. Generative AI turns them into living documents.

Here’s how it works: Every time a machine is repaired, a new part is installed, or a quality issue is logged, that data flows into the AI system. The system then reviews all similar procedures and updates them automatically. No more waiting for the engineering team to revise a document. No more printing 200 copies. Updates happen in minutes.

IBM’s 2024 study found that companies using AI for SOPs cut documentation update time from 6 weeks to under 15 minutes. Errors in procedures dropped by 47%. At Hyundai’s EV plant in Georgia, the AI generated 50+ unique work instructions for different vehicle models-all on the same line. Before, they needed separate teams for each variant. Now, one AI system handles it all.

And it’s not just about speed. It’s about clarity. A veteran operator might know how to fix a jammed extruder by feel. But a new hire? They need exact steps. The AI translates that tacit knowledge into clear, visual, step-by-step instructions anyone can follow.

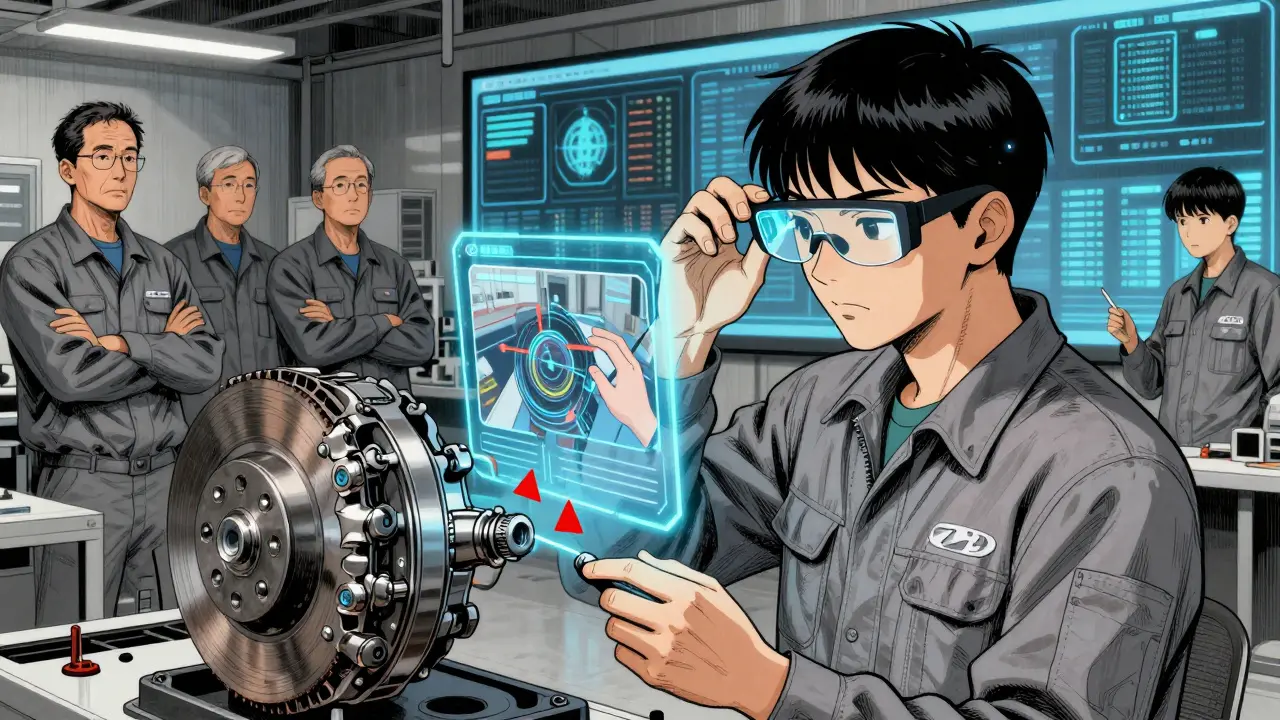

Work Instructions That Learn From You

Work instructions aren’t just read-they’re interacted with. At Bosch’s sensor plant, operators use AR glasses to see digital overlays on real machines. The AI doesn’t just show steps. It listens. If an operator pauses for 15 seconds at a step, the system asks: “Need help with this torque setting?”

It learns from mistakes. If three operators in a row skip Step 4 on a specific assembly, the AI flags it. Maybe the step is unclear. Maybe the tool is hard to reach. The system suggests a revision. Within hours, the updated instruction appears for everyone.

At BMW’s digital twin facility, operators can tap a button to correct an AI-generated step. That correction gets fed back into the model. In six months, accuracy jumped from 76% to 94%. The system isn’t perfect-but it gets smarter every day.

One operator on Reddit put it simply: “I used to spend 20 minutes searching for the right procedure. Now I ask the AI, and it answers before I finish the question.”

Quality Control Reports That Write Themselves

QC reports used to be a nightly chore. Operators measured parts, wrote numbers on paper, and handed them to supervisors. By morning, half were missing. Or wrong. Or lost.

Now, AI pulls data directly from gauges, vision systems, and torque wrenches. It compares each measurement against tolerances. If a part is out of spec, it doesn’t just record it-it explains why. “Torque on Bolt A is 12% below target. Historical data shows this occurs when hydraulic pressure drops below 180 psi. Check valve V-7B.”

At GE’s pilot plant, the AI didn’t stop at reporting. It adjusted the machine’s pressure settings automatically when it detected a pattern. Result? Quality deviations dropped by 39% in 30 days.

And it’s not just for big parts. In food manufacturing, AI generates QC reports for batch consistency-checking viscosity, temperature, and fill levels across thousands of units. No more manual sampling. No more guesswork.

Real Results From Real Factories

The numbers don’t lie:

- At Georgia-Pacific: Time spent searching for procedures dropped from 18 minutes to 3.2 minutes per task.

- At Bosch: New operators reached full productivity 33% faster.

- At Hyundai: Work instruction errors fell by 62% across EV and hybrid lines.

- At a Midwest auto supplier: A bad AI-generated torque spec caused a 72-hour shutdown. That’s the risk-but also the lesson.

That shutdown? It happened because the AI was trained on incomplete data. It had never seen that specific bolt type before. The fix? Add 200 more historical examples. Now, the system flags unfamiliar parts before generating instructions.

That’s the pattern: success comes from data quality, not magic. You need at least 18 months of clean operational data. No data? The AI won’t work.

What’s Holding Companies Back?

It’s not the tech. It’s the human side.

78% of manufacturers say veteran operators resist AI. “Why should I trust a machine over my 30 years of experience?” is a common reaction. But the best implementations don’t replace expertise-they amplify it. Operators become AI trainers. They correct mistakes. They teach the system. That’s how accuracy climbs.

Then there’s legacy equipment. Nearly 41% of U.S. factories still use machines without sensors. No data means no AI. The fix? Add low-cost IoT kits-$200 per machine-to connect old presses and conveyors to the system.

And safety. In 2024, an AI-generated lockout/tagout procedure missed a critical step. Someone got hurt. Now, every major manufacturer requires dual human review for any AI-generated safety procedure. The Association for Manufacturing Technology made it official: no AI can replace a human final check on safety docs.

Who’s Leading the Pack?

The market is split between three types of players:

- Industrial giants: Rockwell Automation and PTC offer AI tools built into their MES and PLM platforms. Great for big factories already using their systems.

- Cloud providers: AWS and Microsoft are pushing industry-specific AI models. AWS’s Manufacturing Knowledge Graph understands 200+ manufacturing terms-from “torque” to “tensile strength.”

- Startups: Tulip Interfaces and RealWear focus on simplicity. Tulip’s platform lets operators create AI instructions with drag-and-drop tools-no coding needed.

By 2027, the market will hit $8.7 billion. Automotive leads adoption at 74%. Pharma lags at 29%-because regulators demand paper trails. But even there, AI is helping draft documentation faster for human review.

How to Get Started (Without the Mistakes)

Don’t try to flip the whole factory overnight. Start small. Pick one high-friction area:

- Start with maintenance. 89% of successful AI projects begin here. Repair procedures are high-volume, high-error, and easy to measure.

- Collect 18 months of clean data. Log every repair, every error, every deviation. If your data is messy, the AI will be too.

- Choose one AI platform. Don’t test 5 tools. Pick one that connects to your existing MES or CMMS.

- Train operators as AI coaches. Give them 40 hours of basic prompt engineering training. Let them correct outputs. That’s how accuracy grows.

- Require human review for safety steps. Always. No exceptions.

Full rollout takes 16-22 weeks. ROI? On average, 11.3 months.

The Future: AI That Fixes Problems Before They Happen

The next leap? AI that doesn’t just report quality issues-it prevents them.

GE’s pilot already does this. When the AI sees a pattern of slight dimensional drift in a casting, it nudges the machine’s cooling rate by 0.5°C. No operator needed. No report filed. The problem just disappears.

By 2030, MIT predicts generative AI could cut manufacturing documentation costs by 65-78%. But the real value isn’t in saving paper. It’s in saving time. Saving mistakes. Saving safety.

The factories that win won’t be the ones with the most robots. They’ll be the ones that give every operator the right knowledge-right when they need it. That’s what generative AI delivers. Not replacement. Reinforcement.

Can generative AI replace human operators in manufacturing?

No. Generative AI doesn’t replace operators-it empowers them. It handles documentation, data analysis, and routine guidance, freeing people to focus on problem-solving, decision-making, and handling edge cases machines can’t predict. The best systems treat operators as trainers, not replacements.

How long does it take to implement generative AI for SOPs and work instructions?

Most mid-sized factories see full deployment in 16 to 22 weeks. The timeline breaks down into: documentation audit (2-3 weeks), building data pipelines (6-8 weeks), fine-tuning the AI model (4-6 weeks), integrating with existing systems (3-4 weeks), and training staff (4-6 weeks). Rushing the data phase leads to failure.

Do I need new hardware to use generative AI on the shop floor?

Not necessarily. Many systems work on existing tablets or smartphones. For hands-free use, AR glasses like RealWear HMT-1 GenAI edition help, but they’re optional. The bigger need is reliable Wi-Fi (1 Gbps minimum) and connecting legacy machines with low-cost IoT sensors-often under $200 per device.

Is generative AI safe for safety-critical procedures like lockout/tagout?

Only with human oversight. A 2024 incident in Europe showed an AI-generated lockout procedure missing a critical step, causing injury. Now, industry standards require dual human verification for any AI-generated safety procedure. AI drafts; humans approve. No exceptions.

What if my factory uses old machines without sensors?

You can still use generative AI. About 41% of U.S. factories have legacy equipment, and many are adding low-cost IoT kits to connect them. These sensors cost under $200 and can monitor vibration, temperature, and cycle counts. Once connected, the AI can use that data to generate accurate procedures and alerts.

How accurate are AI-generated QC reports?

Accuracy depends on data quality. With clean, historical data, AI-generated QC reports are 90-95% accurate in detecting deviations. The real advantage? They don’t just report numbers-they explain causes. “Torque too low because hydraulic pressure dropped” is far more useful than just “Torque: 14.2 Nm.”

Which industries are adopting generative AI for documentation fastest?

Automotive (74%), aerospace (68%), and electronics (63%) lead adoption because they deal with complex, high-mix production and have strong digital infrastructure. Food and beverage lag at 31% due to strict FDA and ISO regulations requiring paper trails. But even there, AI is being used to draft documentation faster for human review.

What’s the biggest risk of using generative AI in manufacturing?

The biggest risk is hallucination-AI making up facts based on incomplete or biased data. A 2024 case at a Midwest auto supplier showed AI generating conflicting torque specs because it was trained on outdated records. The fix? Better data, human review, and continuous feedback loops where operators correct errors in real time.

Comments

Ronak Khandelwal

This is so freaking cool 😍 I remember my uncle working in a factory in Pune-he’d spend hours flipping through binders just to find one torque spec. Now? He just asks his tablet and gets a video demo with emojis telling him when he’s doing it right. AI isn’t replacing him-it’s giving him superpowers. 🚀 Let’s stop fearing tech and start teaching it how we think. #HumanFirst

January 23, 2026 AT 10:59

Jeff Napier

Yeah right. Next they’ll say the AI knows when you’re lying about your lunch break. This whole thing’s a corporate distraction. They don’t want smarter workers-they want easier-to-monitor robots in human skin. And don’t get me started on ‘clean data’-you think some factory in Michigan has clean data? Lol. Wake up. This is just another buzzword shell game.

January 23, 2026 AT 16:36

Sibusiso Ernest Masilela

Oh please. You’re all drinking the Silicon Valley Kool-Aid. Let me tell you something-real manufacturing doesn’t happen on tablets. It happens with grease on your hands and a wrench in your grip. This ‘AI assistant’ nonsense? It’s a glorified PowerPoint slide deck with a voice assistant. And the fact you think 92% accuracy is ‘good’? That’s still 8 mistakes per 100 operations. One mistake can kill someone. You’re not innovating-you’re gambling with lives. Pathetic.

January 24, 2026 AT 10:15

Daniel Kennedy

Look, I get the skepticism. I’ve seen bad AI implementations too-like that time an algorithm told a line worker to use a 12mm socket on a 14mm bolt. But here’s the thing: the solution isn’t to reject the tech, it’s to fix how we use it. The key is training operators as coaches, not just users. At my plant, we gave every shift lead 2 hours a week to correct AI outputs. In 3 months, error rates dropped 60%. The AI isn’t the expert-it’s the apprentice. And we’re the teachers. Stop seeing it as a replacement. See it as a tool that scales experience. Also, yes-add IoT sensors to old machines. $200 is cheaper than a 72-hour shutdown.

January 24, 2026 AT 19:08